Sour service is relates to flammable, dangerous gases that could potentially cause tubing cracks.

When it becomes necessary to expand your exploration to greater depths and further distances, there’s a higher risk of leaks occurring involving sour gas (containing hydrogen sulfide or sulfuric acid) in higher concentrations. At Bighorn Wireline we aim to mitigate your drilling process to avoid leaks of all kinds, but especially the “sour” gas that can wreak havoc.

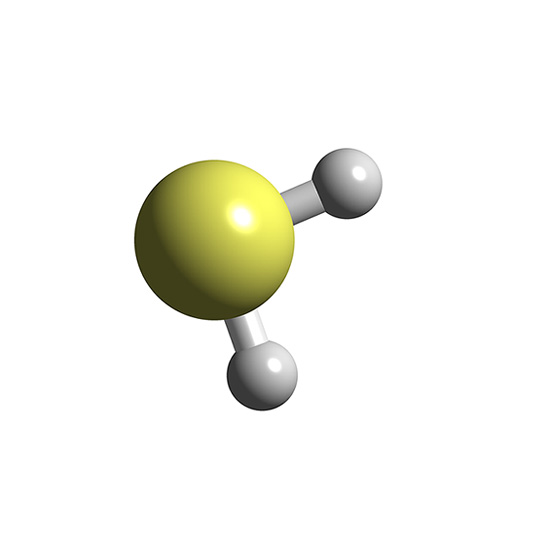

Wireline & Slickline cables must be suitable to the well environment it is exposed to. Hydrogen sulfide (H2S) and Carbon Dioxide (CO2) are two soluble molecules that can be highly destructive to standard wireline cable.

H2S and CO2 form acids in water, which can corrode and embrittle certain metallic materials. The steel used in standard high strength cable armor has a dense grain structure, which is susceptible to these corrosive effects. In many cases, even a brief exposure to low concentrations of H2S and CO2 can lead to cable failure.

Big Horn Wireline has extensive experience working in H2S and CO2 well environments. We take pride in providing safe and quality service under harsh operational conditions.

To better serve our clients, we keep a H2S/CO2 resistant nickel alloy cable ready and on standby at our facility.

Services Include:

- Logging

- Mechanical

- Pipe Recovery

- Perforating